Shipping temperature-sensitive items used to feel like a gamble. Business owners crossed their fingers and hoped that expensive chocolates, fresh produce, or vital medications would survive the journey without melting or spoiling. In the past, the only reliable solution involved bulky Styrofoam coolers and heavy ice packs. These materials cost a fortune to ship and took up massive amounts of warehouse space. The rise of e-commerce demanded a better way, and the shipping industry responded with the insulated mailer. Here’s how insulated mailers revolutionized the shipping industry.

The Engineering Behind the Envelope

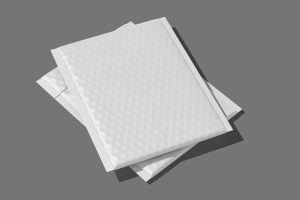

Insulated mailers look simple, but they rely on clever engineering to function. Manufacturers design these lightweight envelopes to maintain a consistent internal environment regardless of external weather conditions. Most mailers feature a durable outer layer, typically made from heavy-duty polyethylene or kraft paper, which repels water and resists tearing.

Inside, the magic happens. A thermal liner, often composed of metalized bubble wrap or specialized foam, acts as a barrier. This radiant barrier reflects heat away from the package during summer and traps warmth inside during winter. This construction creates a thermal shield that protects the contents from extreme temperature fluctuations during transit.

Why Shippers Made the Switch

The shift toward flexible thermal packaging offered immediate benefits beyond just temperature control. While the primary goal remains keeping hot things hot and cold things cold, the protective qualities of these mailers also prevent physical damage. The cushioned interior absorbs shocks and drops, keeping fragile items intact.

Cost savings also drove widespread adoption. Rigid boxes and coolers require shippers to pay for dimensional weight, meaning they pay for the air inside the box. Insulated mailers lie flat and conform to the product’s shape, which drastically reduces package volume. This efficiency allows carriers to fit more packages on a truck, lowering fuel consumption and shipping fees for the merchant.

Protecting More Than Just Lunch

While meal kit companies popularized these mailers, other industries quickly recognized their value. Pharmaceutical companies now trust thermal envelopes to transport life-saving insulin and other temperature-critical medications directly to patients’ doorsteps. Cosmetics brands use them to prevent lipsticks from melting and creams from separating.

Innovation in this space continues to grow. As businesses seek better packaging solutions, they can discover expanding insulated mailers that accommodate bulkier items without the need for a box. These versatile options provide the same thermal protection for odd-shaped goods, further reducing the need for void fill or packing peanuts.

A Lasting Impact on Logistics

The insulated mailer proved that adequate shipping protection revolutionized the shipping industry by showing that it doesn’t require heavy, rigid containers. By combining thermal efficiency with lightweight durability, these envelopes completely altered how companies approach logistics. They offer a solution that protects the product, lowers costs, and improves the customer experience. As e-commerce continues to dominate the retail landscape, these smart packaging solutions will remain a vital tool for brands delivering goods safely to customers around the world.