Running a manufacturing business is a constant balancing act. You are always trying to keep costs down while maintaining quality, all while deadlines loom overhead. If your processes aren’t running as smooth as silk, you won’t just be stressed—you’ll also be losing money.

That’s why you need to take the necessary steps to optimize your manufacturing process for better results. When you tighten up your operations, the benefits are immediate. Here is how you can start refining your operations today.

Analyze Current Processes

You can’t fix a problem if you don’t know it exists. The first step to optimization is a brutal, honest audit of your current workflows. Walk the floor. Talk to the shift managers. Look at the data. Don’t just rely on gut feelings.

The best way to do this is to use established tools like value stream mapping or process flow analysis. These visual tools help you map out every single step a product takes from raw material to the shipping dock. You’ll quickly spot where materials are sitting idle, where bottlenecks are choking production, and where resources are being wasted.

Implement Lean Manufacturing Principles

Once you see the cracks in the foundation, it’s time to get lean. Lean manufacturing is all about stripping away anything that doesn’t add value to the final product. You need to put a serious focus on reducing waste. This could be physical waste (scrap metal), wasted time (waiting for parts), or wasted motion (poor shop floor layout).

Consider implementing Just-in-Time (JIT) production. Instead of stockpiling massive amounts of inventory that eat up cash and warehouse space, JIT ensures you receive materials exactly when you need them. By improving the flow of materials, you reduce clutter and speed up turnaround times.

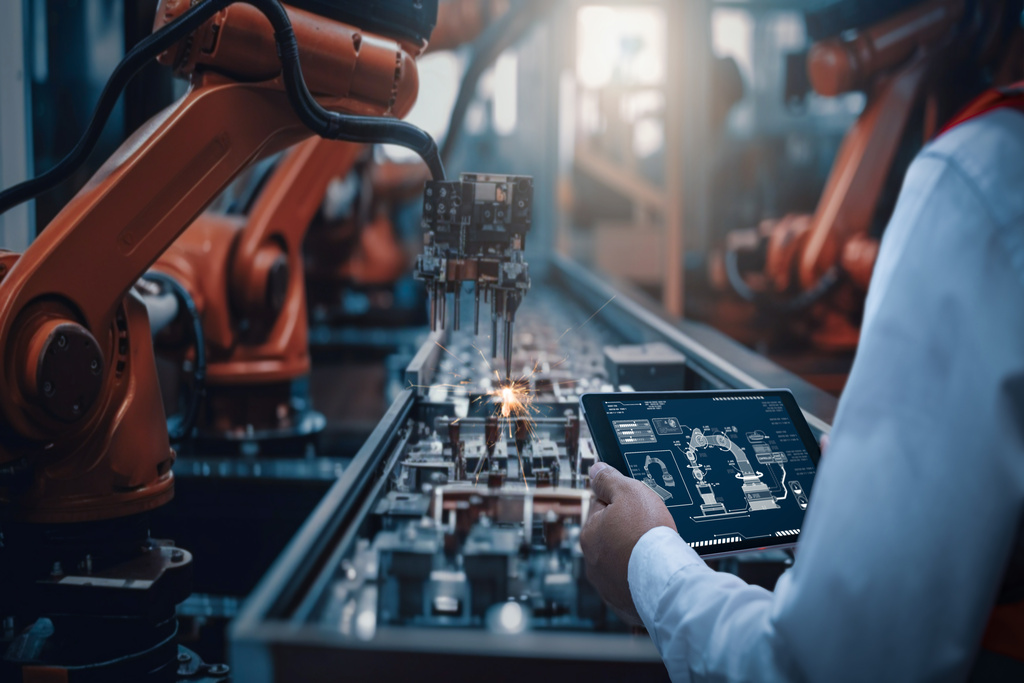

Leverage Technology and Automation

We are in the era of Industry 4.0, and if you are still tracking production on a whiteboard, you are falling behind. Smart technology is the ultimate force multiplier for business owners. Look into the Internet of Things (IoT). Sensors on your machines can track performance in real-time, alerting you to maintenance needs before a breakdown halts the line. Plus, AI can analyze production data to predict demand spikes.

Furthermore, introducing robotics or automation for repetitive tasks reduces human error and skyrockets productivity. For example, automation significantly boosts metal processing accuracy, strengthening your product line and allowing your human workers to focus on complex problem-solving.

Train and Empower Your Workforce

Of course, new technology and lean strategies are useless if your team doesn’t buy into them. That’s why you need to do what it takes to make your employees your biggest allies. Otherwise, you won’t be able to truly optimize your manufacturing process and find better results.

The best way to achieve this is to invest heavily in training. Make sure they understand not just how to use new tools, but why these changes are happening. Even more importantly, listen to them. The people on the shop floor often know exactly where the inefficiencies are hiding. Create a culture where they feel safe suggesting improvements. When your team feels ownership over the process, they become active participants in continuous improvement.